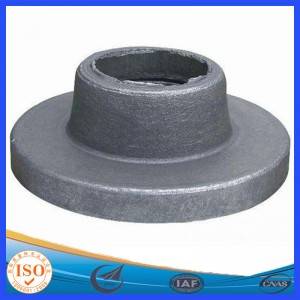

Likarolo tsa ho Forging tsa Boleng bo Phahameng

| Lebitso la Sehlahiswa | Likarolo tsa ho Forging tsa Boleng bo Phahameng |

| Lintho tse bonahalang | 1038,1045,4140 kapa Joalo ka tlhoko ea hau |

| Litlhaloso | Ho latela setšoantšo sa bareki |

| Bokaholimo | Ho qhomisa lehlabathe |

| Mamello | Ho latela tlhoko ea ho taka |

| OEM | Amohela sehlahisoa se ikhethileng |

| Tlhahiso ea Tlhahiso | Ho futhumatsa, ho Forging, Normalizing le ho phatloha ha lehlabathe |

| Kopo | E sebelisoa ho etsa mefuta eohle ea likarolo tse se nang letho |

| Maemo a Boleng | ISO 9001: 2008 Setifikeiti sa sistimi ea boleng |

| Warranty Nako | 1 selemo |

| Kalafo ea Mocheso | Normalizing e tsoetseng pele |

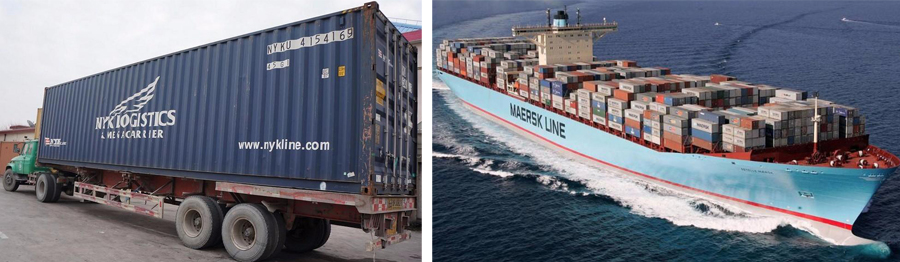

| Sephutheloana | Nyeoe ea lehong, Lebokose la tšepe kapa joalo ka tlhoko ea hau |

| Lipehelo tsa tefo | T/T, L/C, Paypal joalo-joalo |

| Naha ea tlhaho | China |

Ho qapalikaroloke sesebelisoa sa mosebetsi kapa se se nang letho se fumanoeng ka ho forging le ho holofatsa tšepe e se nang letho.The mechanical properties of metal billet e ka fetoloa ka ho sebelisa khatello ho etsa hore e hlahise deformation ea polasetiki.Ho ea ka mocheso oa sekheo nakong ea ts'ebetso, forging e ka aroloa ka serame. forging le chesang forging.Mohatsela forging e ka kakaretso e etsoa ka mocheso kamoreng, ha chesang forging e etsoa ka recrystallization mocheso holimo ho feta ba tšepe billet.The looseness ea tšepe e ka felisoa ka forging.Hole, e le hore thepa ea mechine ea forgings. e ka ntlafatsoa